Eames Tandem Seating

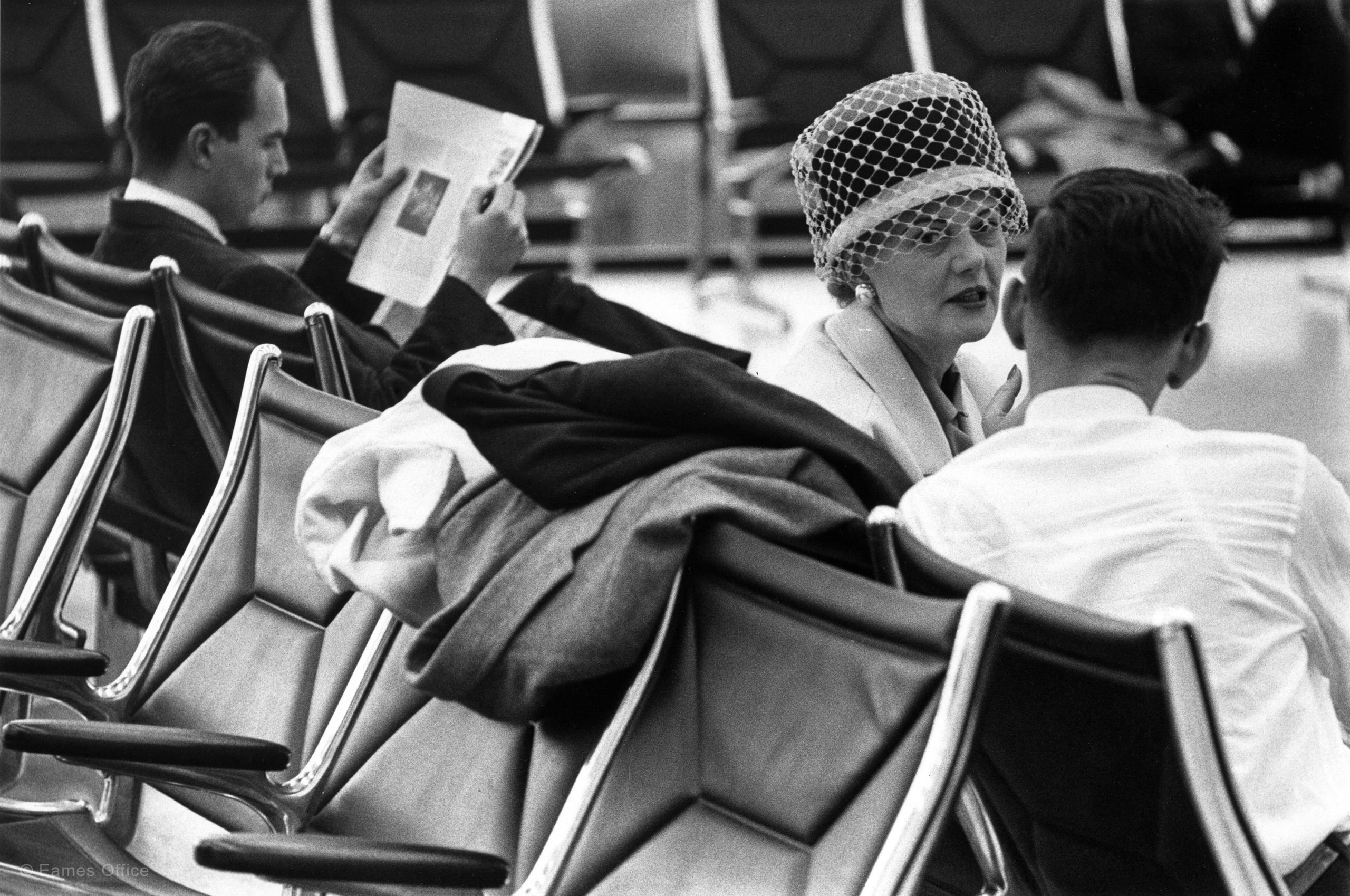

The Eames Tandem Seating design can be described in clinical terms. Nylon-covered sling seats are suspended in tension on a cast, polished aluminum frame, and are attached to an iron T-Beam in single rows of 2 to 6, in double rows of 10 or 12, or in combination with tabletops.” A heat-sealed sandwich of synthetic material, vinyl foam, and Fibrethin (similar to the formulation of the Eames Aluminum Group slings, but with a unique scoring pattern appropriate to the shape of these) is held between polished cast aluminum arms. The scoring helps keep the padding in place. Seat and backs are identical and interchangeable and can be changed on the spot in the event of wear or vandalism.

It seems straightforward enough, but there were many steps and much thinking involved in creating what we now call “the best in airport seating.” Charles often found himself having to explain to people that the “visual” was not the way they approached design. What’s particularly interesting about how Charles and Ray Eames approached the development of this design is the elaboration on what, instead of “the visual,” was important in the Eames design process. The important considerations were: “fitness to need,” budget, durability, maintenance, and replacement.

In an interview, Charles Eames explained their approach to this design:

“Occasionally, we work on a piece of furniture without any specific application in mind—but that is the exception. Usually, the development of a design is triggered by some real and immediate need—a need of our own, or that of a friend, or a building or a situation. In the case of Tandem Seating, C.F. Murphy Associates, via O’Hare Airports, provided the trigger. Our response could not, however, be completely impersonal—not with the amount of air travel we do these days.”

The Eames Office partner, Herman Miller, gladly provided the money for development. By this time, long time founding chairman of Herman Miller, D J DePree had retired, and the company was run by his son, Hugh De Pree. In the same interview, Hugh explained the technical aspects of the work: “Upon completing a mock-up, then a prototype, the Eames Office put the seating through basic tests. Herman Miller’s Technical Center subjected this prototype to the following tests: a 100-lb padded weight was dropped in a 5-in. free-fall onto a seat pad 15,000 times; arm, seat, and back-pad materials were subjected to 100,000 cycles on a Wyzenbeek abrasive test machine; seat and back-pad material were chilled at -15F for 30 minutes, then folded and run through a wringer; seat and back-pad material were exposed t 120 hours of ultraviolet light, 65-70 percent relative humidity, and to 105F ambient temperature.”

The exhaustive, accelerated testing the Eames design was given convinced the airport developers that it was very durable and would require little maintenance over years of hard wear and tear. Hugh De Pree came to the following conclusion: “Herman Miller did not analyze the market for public seating before deciding to produce this new seating group. …We are depending on the validity of the design and on the quality of its manufacture to create a demand for Tandem Seating.”

The Eames Office used the O’Hare and Dulles Airport projects as prototypes for the entire program.

Charles Eames concluded his interview with a very interesting observation. “Two gratifying things about the project can be directly attributed to the architects: the architectural background within which the seating worked was sound and consistent; and the architects were content to consider black as a color.”

Carter H. Manny, who supervised the project for O’Hare Airport, summed up their decision to adopt the Eames design: “Eames Tandem Seating was finally selected over the other submissions because it met our requirements more than any other design. It was easily as comfortable, perhaps even more comfortable, than units with conventionally upholstered seats and backs, yet the back and seat in this Eames design are simple reinforced pads, identical, interchangeable, and capable of quick-low-cost replacement. This replacement factor was also constant for the polished, cast aluminum legs and frames, which are assembled with mechanical joints. It was a key factor in deciding on the Eames unit. None of the other designs submitted had such a feature.”

We’re not aware of any other airport seating that ticks all of the boxes. That’s why we call Eames Tandem Seating the best in airport seating. Hundreds of airports around the world provide Eames Tandem Seating to their guests, and it is suitable for many types of public places. Some Apple Stores have equipped their in-store theaters with ETS. The design is available in Europe and the Middle East from Vitra, and available in the United States and the rest of the world from Herman Miller.

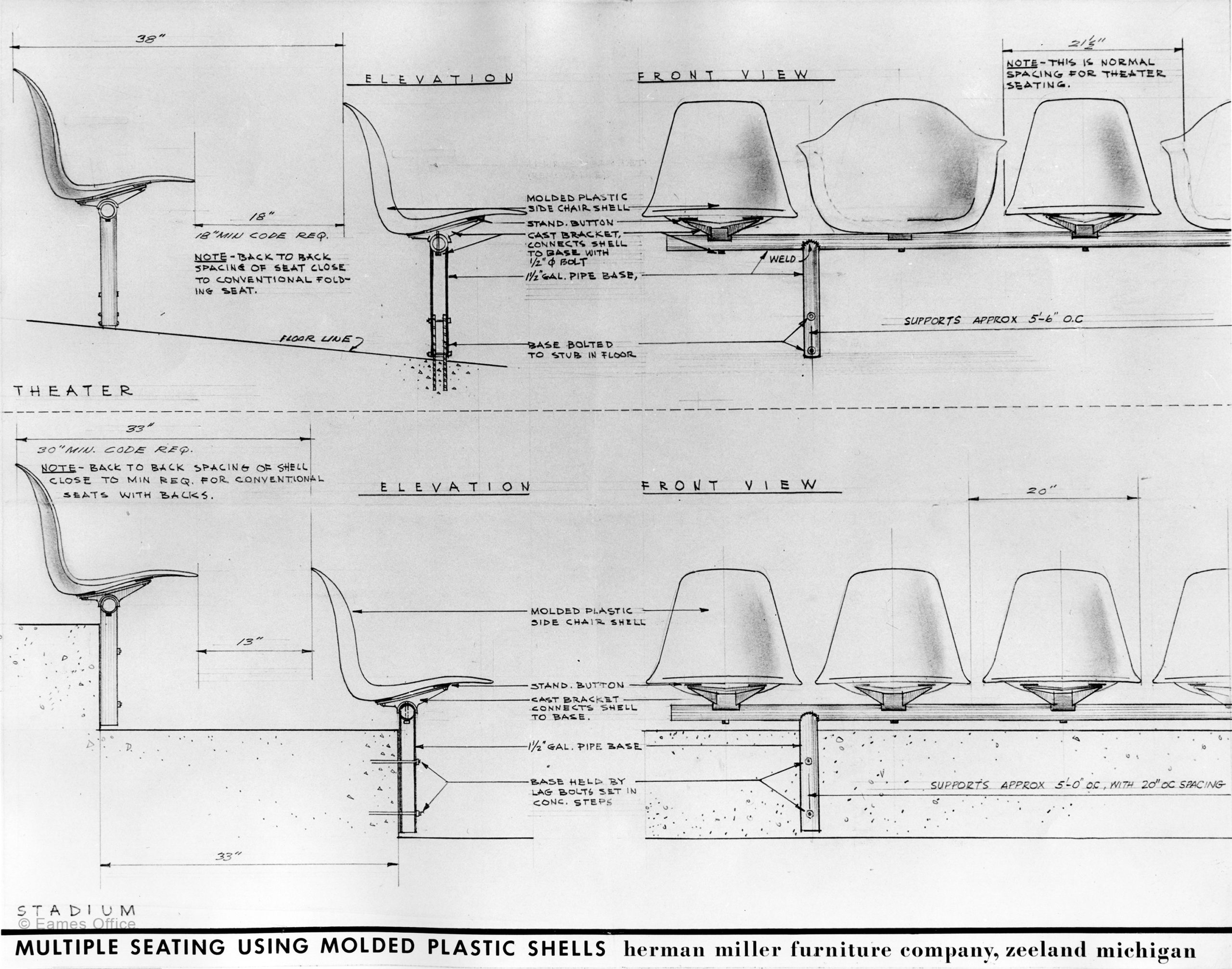

Concurrent with their work on Tandem Sling Seating, Charles and Ray Eames also developed Tandem Shell Seating. The two lines of “Tandem” furniture share one common design element: a steel bar to provide stability to long runs of seats. These continuous steel beams are strong enough to permit large clear spans, affording exceptional ease of maintenance.

Like the Tandem Sling Seating, the Tandem Shell Seating was designed primarily for public spaces. Either type of seating could help organize space and provide definition. The Eames Tandem Shell Seating was more likely to be found in reception areas of offices or defined spaces in retail stores. For example, two Tandem Shell rows could serve very well as a department store’s shoe department. In the same way as with the Tandem Sling Seating, any of the spots on an Eames Tandem Shell bench could be equipped with a table instead of a chair.

Our partner Vitra still makes the Tandem Shell Seating in a variety of lengths.

Explore Similar Works

Related Products

Browse a curated selection of Eames Office products we think you’ll love