Eames Molded Plastic Armchair

In their lifetime, Charles and Ray succeeded in making one-piece “surfaces to receive the body” only twice: with molded plastic and with molded and welded steel wire. The Eames Molded Plastic Armchair came first, and it’s interesting to note that the form of these chairs was first worked out in metal, not plastic, because Charles and Ray were “material agnostic.” Charles and Ray didn’t set out to make metal or plastic, or wood chairs. Instead, they set out to meet the need for certain types of furniture, and they had no preconceived ideas as to what materials would work best—they sought out the best material, with the need foremost in their minds.

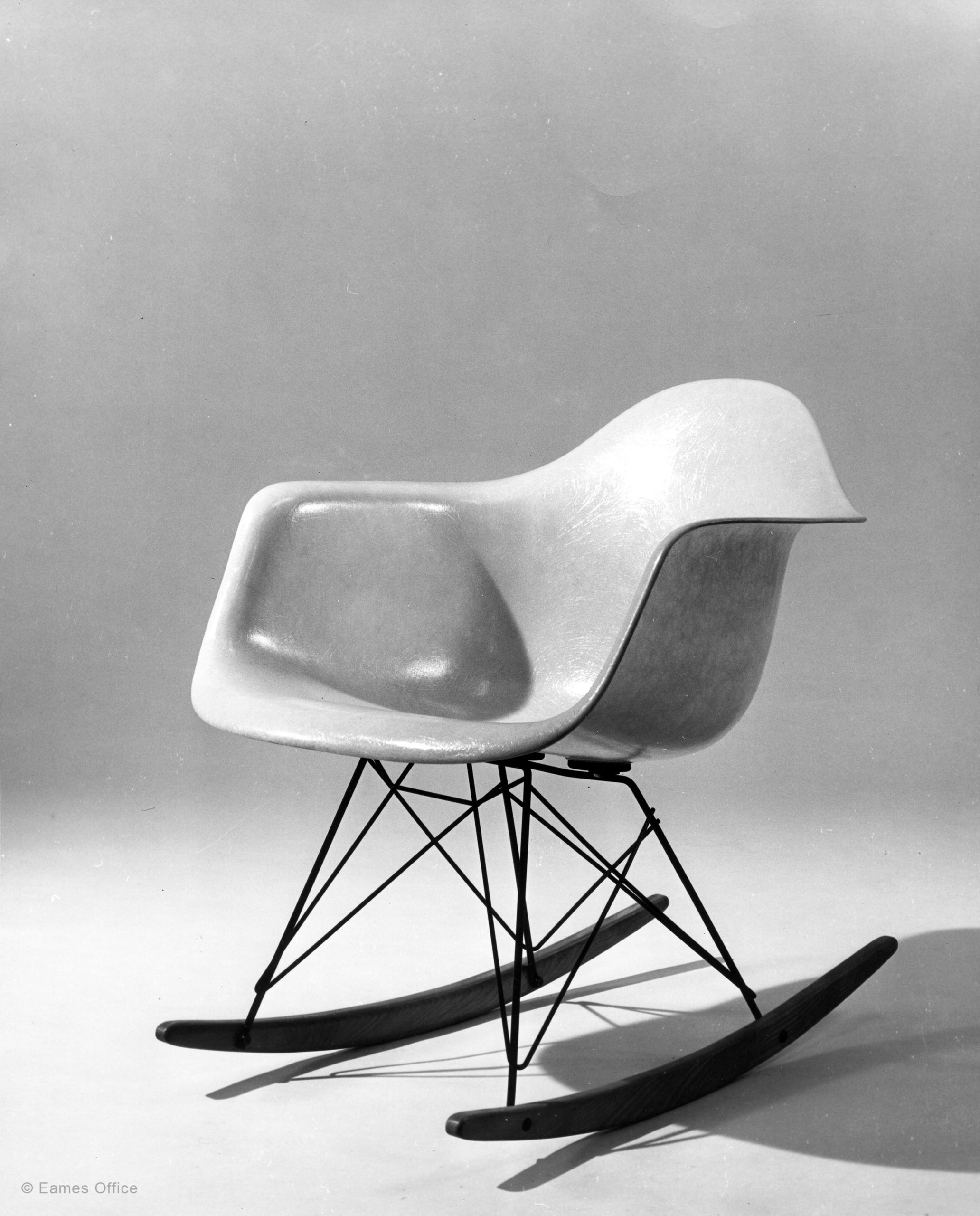

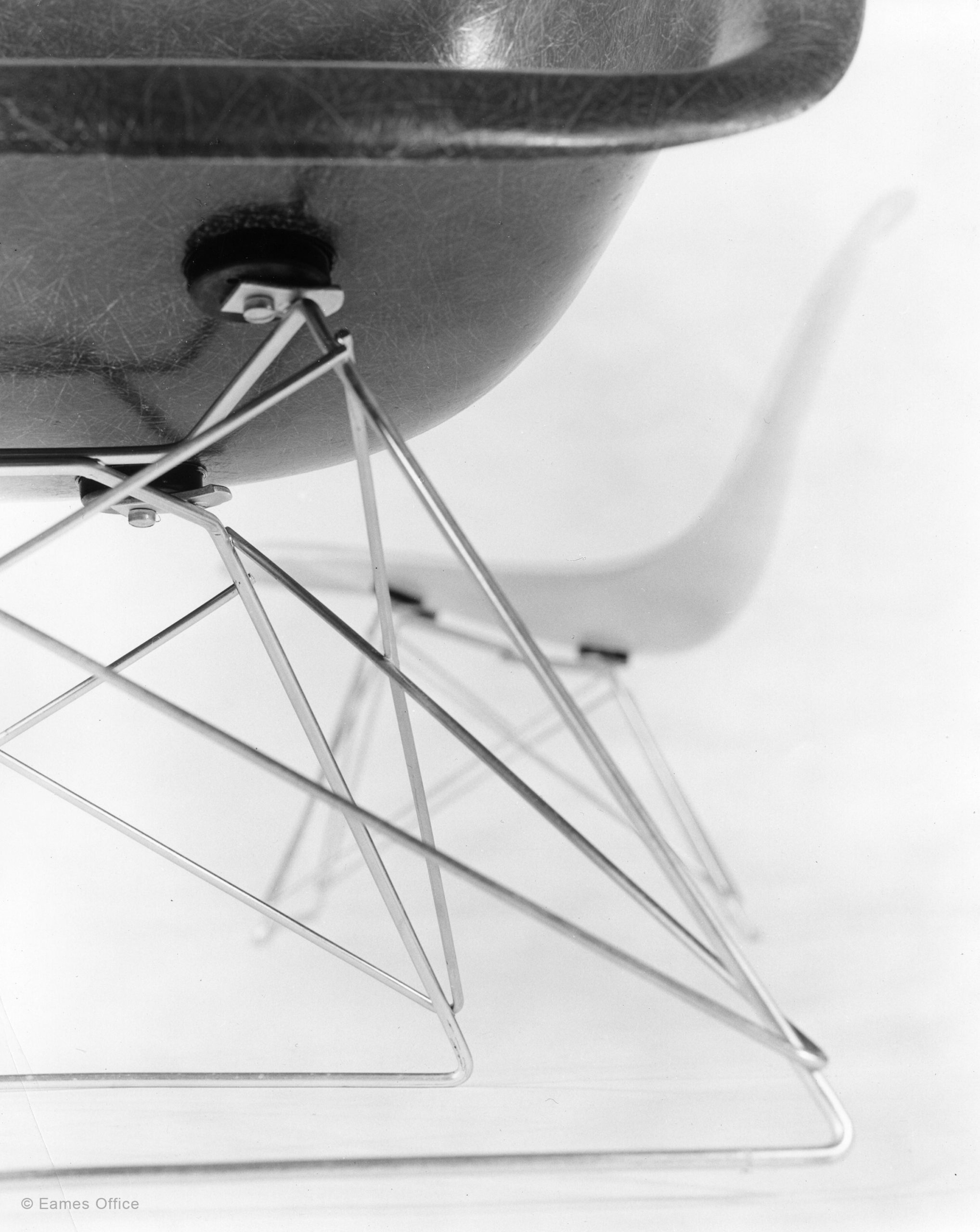

A 1949 Museum of Modern Art competition gave a jet assist to the Eames furniture development. As previous award-winners, the Eameses were granted $5000 by MoMA to lead a research group into new low-cost furniture. The result of their process was what they entered into the competition: one-piece shells, in both arm and armless forms, with a great variety of structural options, to provide the “proper relation to the ground” for the shells, constructed of stamped steel coated in neoprene to moderate the surface temperature of the metal. The Eames entries took second place. The judges mainly complimented the system of bases: which included standard four-legged bases, rocking chair bases, a low base made out of steel wire, and even a contract base of cast aluminum.

At this point, on the third anniversary of their relationship with Herman Miller, the Eameses were for the first time met with resistance. Herman Miller balked at spending $80,000 for a steel stamping press for a design that had no precedent in the marketplace. So Charles and Ray turned to another wartime technology: fiberglass molding. Fiberglass was only invented in the 1930s, and its use during World War 2 was restricted to military applications. For example, it was used on military airplanes in the form of molded cones called “radomes,” to protect delicate electronic equipment, such as antennas, from the elements.

For proof of concept, the Eameses hired a fiberglass fabricator named John Wills to make two models of their arm shell shape in fiberglass. One of those two models is still with us today, and you can see it on display at The Henry Ford Museum, where Charles and Ray are featured with their own exhibit, contextualized with other great inventors like Luther Burbank, the Wright Brothers, and Thomas Edison.

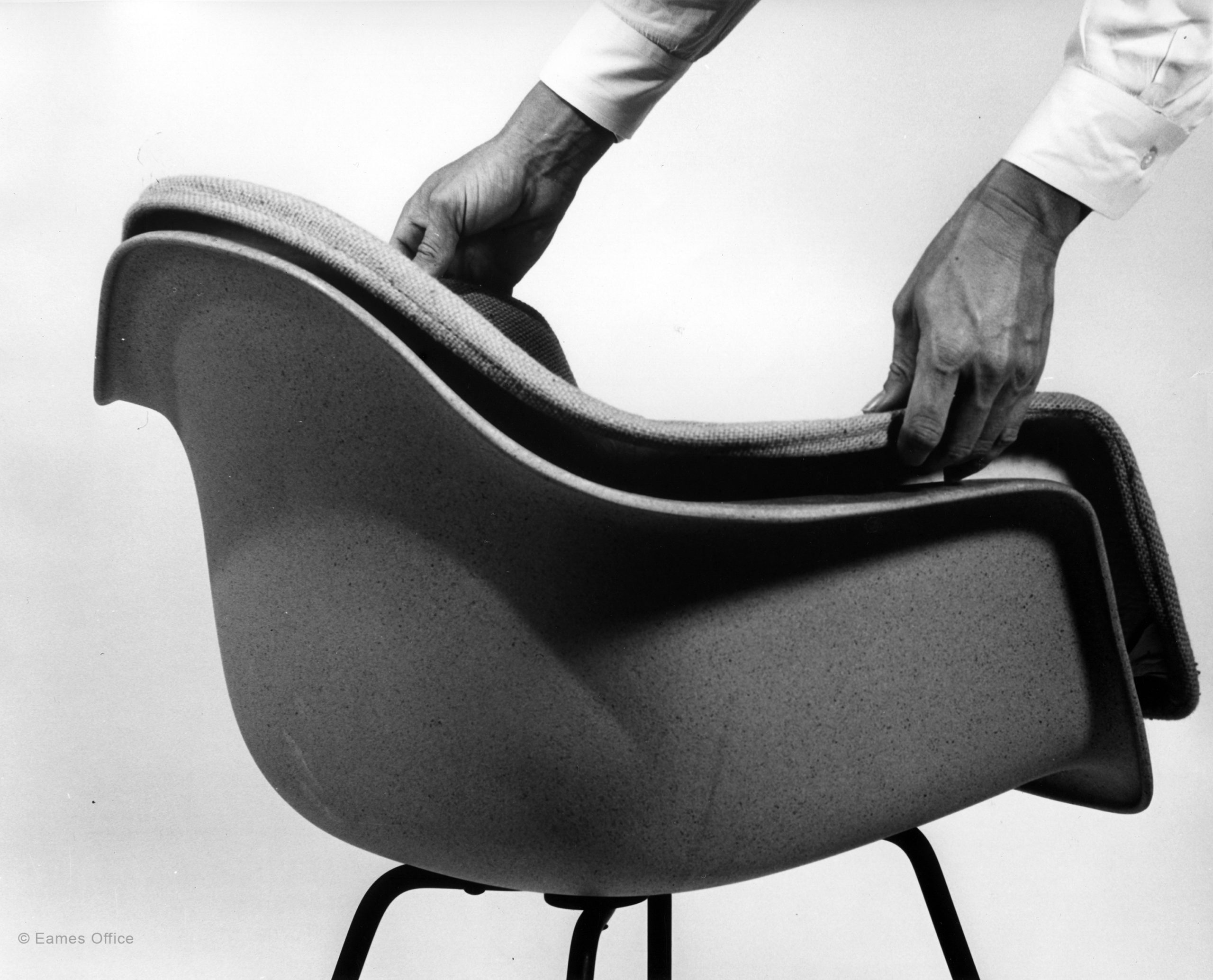

With a full-size, three-dimensional example to test out, Charles and Ray were confident that fiberglass would be even better for their shell chairs. It was naturally resistant to extremes of heat or cold, meaning they wouldn’t need to coat it! Rubber shock mounts, which worked so well with the molded plywood group, could likewise be used with these shells to attach the legs to the shells while providing added flexible comfort. They drafted two people, Irv Green and Sol Fingerhut, of Zenith Plastics, their production partners. When Irv and Sol met Charles and Ray, they had only ever made radomes for airplanes. However, Green and Fingerhut were so eager to get into the furniture business and were so taken with these designs that they not only proposed a $5000 cost of machinery; they agreed to pay for half of the cost themselves. Herman Miller paid the other $2500.

Charles Eames described their innovative technique for molding the plastic shells in these words: “The reinforced polyester was a special technique developed for areas that demanded a high-performance material. Essentially this meant the aircraft industry that could afford big investments for the development of material and tooling. Our object was to make this high-performance material accessible to the consumer in a chair that would ultimately give it a high performance per dollar. The problem wasn’t so much one of form. “The real problem was to make this essentially industrial material available at the consumer level. At first we had very clear ideas of the kind of surface we wanted to maintain, but eventually we realized that anything would do just as long as it was uniform. Uniformity, uniformity…eventually we realized that this was what we were striving for, and that actually it was the toughest thing to get.”

The contract for the first production chairs was signed in November 1949, and to an audience of business people, the chairs were first shown at the Chicago Merchandise Mart in January 1950. The chairs had their big public debut when they were presented with the other prize winners of the Low-Cost Furniture Competition. By the time of the opening, both the catalog and the name of the exhibition had evolved. The show and book were called “Prize Designs in Modern Furniture.” One suspects that in 1950, retailers were reluctant to advertise “Low Cost” furniture. The New York City retailer who presented the designs for sale was “Sachs Quality Furniture,” and their sale coincided with the museum exhibition.

In the first year of production, the fiberglass chairs were available in only three colors: greige (grey-beige), elephant hide grey (light black), and parchment. The colors are an Eames design story in and of themselves. Before Charles and Ray Eames had the idea to make furniture for the home out of fiberglass, fiberglass has mainly been used in places where its appearance didn’t matter. “Radomes” on military airplanes were made of the “natural color” of the fiberglass mixture, with no added pigments. To make the most useful furniture, Charles and Ray spent dozens of nights at the Zenith factory, mixing up different combinations of pigments, to achieve colors that they felt would work in most home or office environments. At launch time, they had only three integral colors ready, the ones highlighted in the Sachs ad. Eventually, in later years, the Eames fiberglass chairs were offered in as many as 30 different colors.

In the twenty-first century, we’ve taken those same timeless forms and rendered them in new materials. First, in 2006, we worked with Herman Miller to bring out the Eames Molded Plastic Armchair in polypropylene, a material lighter and weight and more environmentally friendly than the original fiberglass formulations. These have proven to be a big hit in contract settings, where they must endure a lot of wear and tear. In 2012, using a new proprietary technology sourced by Herman Miller, we achieved a dream that had eluded Charles and Ray: a one-piece molded wood chair.

Explore Similar Works

History

Related Products

Browse a curated selection of Eames Office products we think you’ll love