Additional Information

The splint conformed to the human leg, offering ideal support through its natural form. In fact, to make the splint, the design duo used Charles’s leg as the model–apparently, an extremely painful process since removing the cast ripped out all his hair.

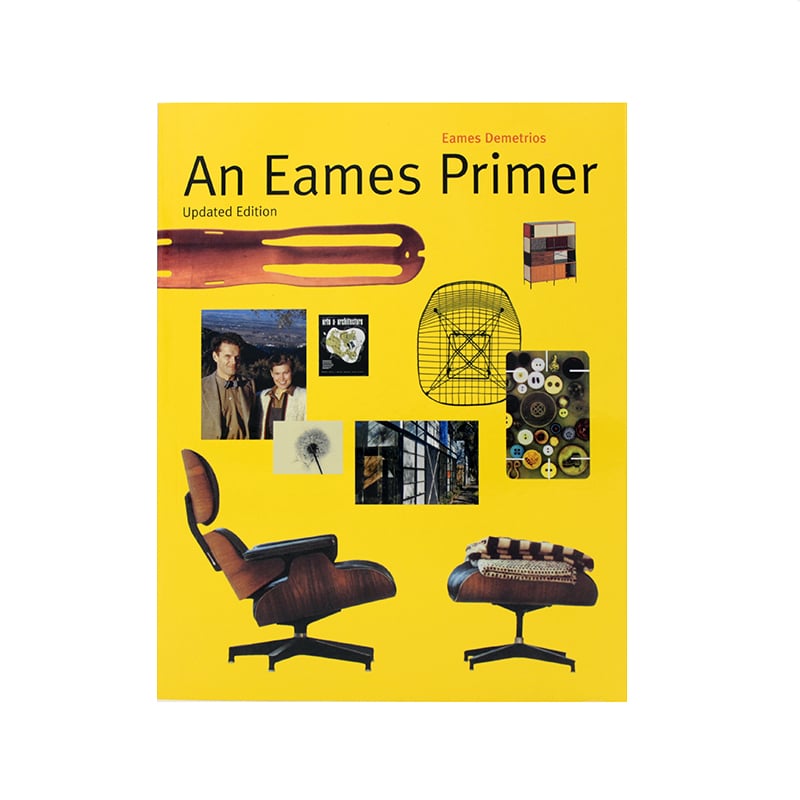

“It also was an extremely honest use of materials, wedding the Eames understanding of the limits of the material to the functional needs of the splint,” says Eames Demetrios in An Eames Primer. “Symmetrical holes relieve the stress of the bent plywood, but also give the medic a place to thread bandages and wrappings. The splints represent a perfect example of utilizing to advantage what the Eameses called the constraints of a particular design problem. Recognizing and working within these constraints was always key to their design process. It was not always easy.”

Charles and Ray had created a great design; however, they ran into a problem that many young designers encounter: Financing. This ultimately led to a partnership with John Entenza and Colonel Evans of Evans Products. Now, with the financial support and also a large production facility, the husband-and-wife team were equipped to handle production on a much larger scale than was possible in their Los Angeles apartment guest room.

By the end of World War II, it is estimated that 150,000 splints were made and used. “The Eameses, evolving into the Eames Office and the Molded Plywood Divison of Evans products, had developed and nurtured a fabrication process and even built the actual tooling that made the splints.”

The design led to other wartime molded-plywood work as well, including an airplane fuselage, airplane stabilizer tail, an arm splint, a body litter, and a pilot seat.

“Charles and Ray were beginning to strike what would become their characteristic balance of idealistic vision and realistic implementation.”

Eames Demetrios, An Eames Primer

“Although the military is not the same as a consumer market, it is still a market. And making something that people actually needed was immensely more satisfying than the simple statement of principle that the organic chair embodied.” Demetrios wrote. “On a practical level, the splints led to self-sustaining rather than obligatory production. Charles and Ray were beginning to strike what would become their characteristic balance of idealistic vision and realistic implementation.”

In 1945, with a sense that the war would soon be coming to an end, the Eames Office turned its attention back to furniture. Including the people building the splints, the Office was now 15 employees strong. The next 12 months would prove to be pivotal for Charles and Ray. It was the year that the last five had led up to—the year the the Eames LCW would be born.

Explore Similar Works

Related Products

Browse a curated selection of Eames Office products we think you’ll love