Eames Molded Plastic Side Chair

The sourcing of fiberglass for modern furniture was very forward-thinking. In 1949, when Charles and Ray made this decision, no mass-produced furniture was made in fiberglass or any plastic. However, Charles and Ray wanted to give consumers the benefits of robust, lightweight, and durable industrial materials. So they tapped two engineers who at the time made fiberglass parts for military airplanes to work with them to achieve this design breakthrough. This would later lead to the Eames Molded Plastic Side Chair.

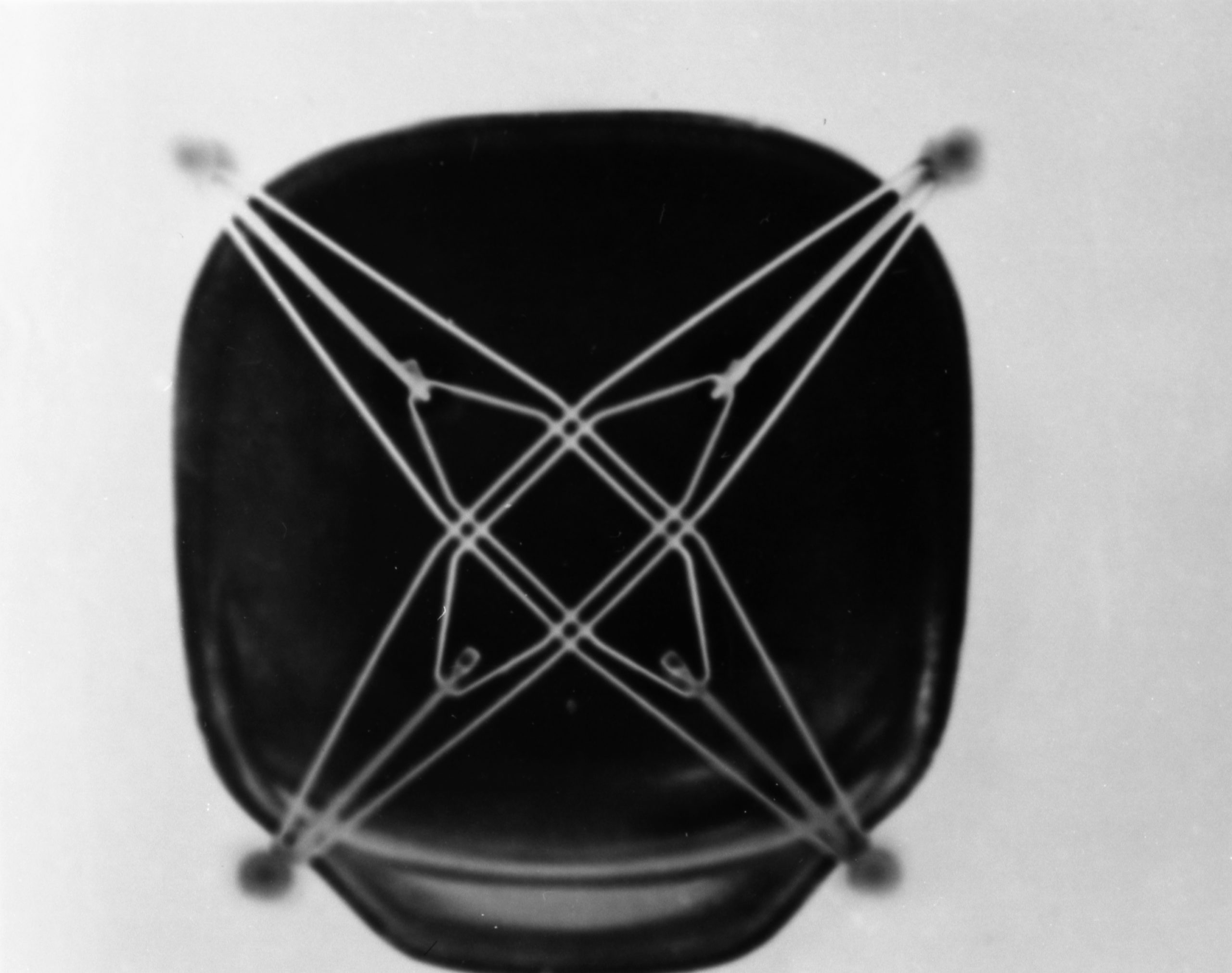

When the shell chairs first came out, Charles and Ray made a dining or desk height model with a four-legged base. But they didn’t stop with that. That original four-legged base chair weighed 18 pounds, and they felt they could do better. So they crafted from steel wire another four-legged base, the one collectors love to call the “Eiffel Tower” base, which resulted in an equally sturdy four-legged chair, but one that was four pounds lighter.

It is ironic that when the Eameses set out to make the first shell chairs, they decided to focus first on the arm shell because they assumed that it was the more complicated form to produce. However, the arm shell was relatively straightforward in practice compared to the Eames Molded Side Chair. In addition, the arms and sides of the one-piece arm shells provided more sound structural stability than they could achieve with the very first side shells.

The side shells proved so vexing (the prototypes tended to crack) that after introducing the arm shells, they turned their attention to the upholstered wire chairs next to fulfill the need for side chairs. Only after the Upholstered Wire Chairs, which have the same shape as the side shells, were launched did they return and complete the side chair forms in molded plastic.

Even when they added more thickness to the side chair form, the first production side chairs tended to crack where the back of the shell curved up from the seat. As a result, after putting the molded side chairs into production and for sale, the Eames Office had to revisit the form. After two years of selling the side chairs, the Eames Office responded to feedback about developing cracks and made an even thicker shell. It is the thickness of the second iteration of the production side shells that we still use on these chairs to this day.

The bases, the devices to elevate the sitter to the desired height, is another reflection of Charles and Ray’s thoughtfulness. All of the shells can be fitted with any number of bases to create chairs to satisfy many seating needs. There are lounge height bases, dining or design height bases, counter height bases, and contract bases, which are very sturdy and can be equipped with casters and even tilt-swivel mechanisms to be used as office desk chairs.

This system of bases further elaborates the Eameses thought of keeping the cost low because at least 50 different Eames shell chairs can be made from the one standardized shell.

Both Herman Miller and Vitra still produce the Side Chairs today.

Explore Similar Works

History

Related Products

Browse a curated selection of Eames Office products we think you’ll love