1943 Plywood Sculpture

Few of their earliest breakthrough artistic experiments would merge art and technology so perfectly as their iconic 1943 Plywood Sculpture, which embodies the pioneering spirit of Charles and Ray’s personal relationship, multidisciplinary working partnership, and wholly original thinking.

Characterized by delicate changes in thickness and graceful three-dimensional curves, the groundbreaking, innovative molding techniques worked out through the Plywood Sculpture would give rise to some of the most important furniture designs of the 20th century. Only two sculptures were made in 1943. After a rigorous year-long research and production process the Plywood Sculpture is now available as a limited edition of twelve – celebrating eighty years of Eames Office.

“Charles and Ray’s sculpture represents a pivotal moment in their work, in their lives, and in design history and continues to inspire all that encounter its beauty today. For Charles and Ray, art was the best way to test the technology and technology was the best way to make the art.”

Eames Demetrios, Director of Eames Office

In a sense, the Eames Office takes shape with Charles and Ray’s courtship letters and begins with a wedding held at a friend’s Chicago apartment on June 20, 1941. This was the moment when Charles and Ray Eames became partners in life and partners in design, joined together by their love of creation, and passion for solving problems that needed to be solved. Immediately after the wedding, the couple moved west and lived in a Hollywood hotel as they got to know Los Angeles and make new friends, one of whom was John Entenza, publisher of Arts and Architecture magazine, who introduced Charles and Ray to Richard Neutra. The architect had recently completed his Strathmore Apartments, which is where the Eameses came to live. It would be two years before the Eames Office moved to 901 Washington Boulevard in Venice, California, so the Neutra apartment initially served as a working laboratory, and home to a tool that helped shape (literally) the future of modern design: The Kazam! machine.

A curved plaster mold threaded with powerful electric coils wired directly – in a death defying move by Charles – to a transformer on a nearby power pole, the Kazam! machine was a homemade device for molding plywood. The process required extremely thin sheets of wood veneer to be sandwiched with glue, clamped tightly in the hot mold, and then held in place for four to six hours by a rubber balloon inflated by a bicycle pump. Charles and Ray would repeat these steps – in their small apartment, where they had to sneak in the materials at night by climbing sixty-five stairs in the dark – as many as a dozen times to create one piece of curved plywood.

The Kazam! machine was the couple’s first significant hands-on experience with molded ply. With this machine they’d successfully designed and figured out how to mass-produce a U-shaped leg splint for

the U.S. Navy in 1942 but mastering how to make molded forms with compound curves was still uncharted territory, for the Eameses and all designers worldwide. Even large-scale furniture companies hadn’t succeeded, a fact Charles and Ray were aware of after watching two manufacturers attempt and ultimately fail to mass-produce the Organic Chair, Charles Eames and Eero Saarinen’s winning entry in MoMA’s 1940 Organic Furniture competition.

After the MoMA competition, for which Ray, then Ray Kaiser, worked on the drawings for its final presentation, Saarinen moved on to other projects. The Eameses, however, were determined to solve what they didn’t see simply as a manufacturing problem, but rather a design problem. They knew that if they were going to create an organically shaped, single-piece molded chair that could be mass-produced and whose design would optimize the manufacturing technique rather than fight it, then they’d have to figure out that technique themselves.

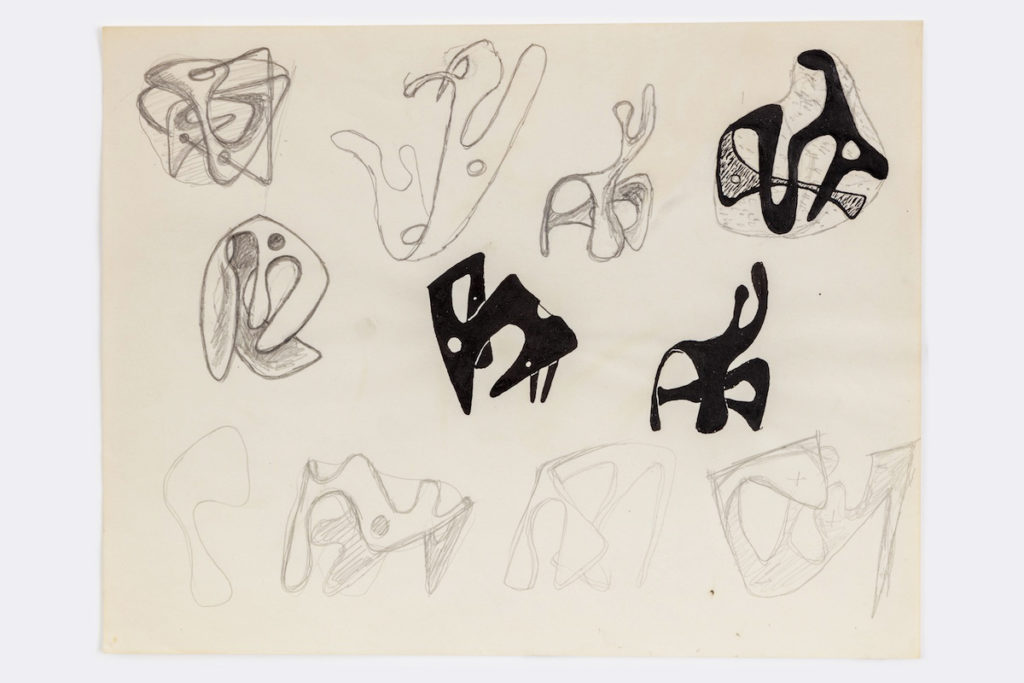

Anyone familiar with the thirty-seven-year brilliant career of Charles and Ray Eames knows how this story ends, but what you may not know is that everything they created – furniture, films, World’s Fair exhibitions, architecture and more – and how beauty and functionality are never in conflict in any of their work, all began with a sculpture – sketched on a small scrap of paper that would fit in the palm of your hand. Sketched in pencil, the drawing on this paper, circa 1943, is by Charles and Ray Eames. In the center is an organically shaped form, which we now know to be a sculpture, and all around it are notes and measurements written in two styles of handwriting – the quick, loopy cursive of Charles, and the neat, artistically drawn script of Ray.

“Charles and Ray always said that their early hands-on experience with molded plywood was essential to their development because it required them to design a lot of tools. They realized that when you design a tool you need to have a really good idea of what that tool is going to do. They took that idea with them in everything they did – and it started with their early experiments with molded ply.”, says Eames Demetrios.

To understand the constraints of plywood, Charles and Ray designed experimental shapes to be the best possible test for pushing the envelope on curves. In 1942, they made a first small sculpture, most likely using the Kazam! Machine in their apartment. This sculpture, which has since disappeared, had one same wall-thickness throughout. Building on knowledge gained in production of their molded plywood legsplints, the couple began experimenting with even more complex organic shapes, thinner sections and varying numbers of layered veneers. They realized that the molding process was not sophisticated enough for any of these challenges so they started using stronger presses and metal sheets on the molds. This process of iteration and ability to surrender to the journey is a thread in everything Charles and Ray designed.

With its abstract organic shape, the 1943 Plywood Sculpture was not only a beautiful work of art but also a technological breakthrough in the amount of control they were able to achieve. Being able to make the curves three-dimensional and precisely guided represents a pivot point in the Eameses’ understanding of plywood, and a pivot point in midcentury modern design. The objects we live with – how they’re made and what they look like – were forever changed by this hands-on, problem-solving approach of Charles and Ray Eames.

“In a sense, their chairs are tools for living and the sculpture is a tool for beauty. One of the main threads in Charles and Ray’s work is that art and technology are united.”

Eames Demetrios

Before enrolling to Cranbrook and ultimately founding the Eames Office in California, Ray Eames was a promising young artist in New York City. From 1933 to 1939 she studied with abstract expressionist painter Hans Hofmann. Her paintings and collages were shown in several publications and exhibitions of the American Abstract Artists group of which she was a founding member. Feeling discontent with the limiting nature of painting and looking to learn more about architecture and the three-dimensional space, Ray went to Cranbrook in 1940. As Ray later said: “I never gave up painting, I just changed my palette.”

The Plywood Sculpture is a perfect synthesis of artistic expression and experimental yet rigorous technical expertise. As a Christie’s catalogue puts it “the sculpture unites the parallel narratives of fine art, sculpture and industrial design.” In 1943, Charles and Ray Eames made two sculptures in an experimental mold, one of which was exhibited at New York’s Museum of Modern Art in 1944. After being exhibited at MoMA’s “Design for Use” exhibition, the sculpture was purchased by curator Serge

Chermayeff, and today it is in the permanent collection of the Vitra Design Museum in Germany.

However, this wasn’t the one that the Eameses kept for themselves. Both sculptures were made in the same production tool but, due to the natural properties of wood and the fact that veneers have a tendency to warp after being removed from a mold, they are not identical. The legs are positioned in a slightly different way, which changes the feeling of the piece and how it activates a space, and one sculpture has a more contrasting veneer pattern.

The sculpture that the Eameses kept for themselves stayed in the hands of the Eames family for decades, and it is now held in a private museum collection. It is this sculpture, the one cherished by Charles and Ray as well as the entire Eames Office, on which the limited edition Plywood Sculpture is modeled.

Plywood Sculpture – Limited Edition

The notion of an edition of the 1943 Plywood Sculptures has long been considered – and any time the historic sculptures have been displayed visitors were fascinated by both the form and its meaning. The decision to produce a limited edition began in early 2020 with a conversation at the Eames Office, the California-based, third-generation family-run team dedicated to communicating, preserving, and extending the work of its founders, Charles and Ray Eames.

The twelve limited edition Plywood Sculptures were made possible by the Eames Office team and craftspeople in a German manufacturer’s studio. Together they spent more than a year working on a puzzle solved by Charles and Ray in 1943. They had to remaster what the Eameses had mastered seventy-eight years earlier, but there were no blueprints, no how-to guide. To succeed, they’d have to think like Charles and Ray and follow the clues inherent in the object itself.

Today’s state-of-the-art tools like 3-D scans and CAD software were of some help, but the most crucial information came from the original sketches and paper patterns. It was on those sketches that today’s

team could see Charles and Ray figuring the process out for themselves. What worked and what didn’t wasn’t always clear so today’s team would try things and experience the same discoveries that the Eameses uncovered. They were repeating the cycle of discovery and learning, figuring out the form and building the necessary tooling, mastering the process one failure and triumph at a time.

“What the Eameses did in 1943 was highly sophisticated. How they used layers of these really subtle thicknesses of veneer was something that wasn’t done commercially until the early 1990s. There were no examples for them to follow because they were the first ones to do this, which meant that they had to imagine what the veneers could do, and then figure out how to do it. The limit of what is possible lived in Charles and Ray’s imagination.”

Felix Buddenberg, Senior Engineer of the German Manufacturing Team

To create the limited edition sculptures, all the Eameses’ original techniques were used, which meant the team also had to figure out the tools behind those techniques. We had to think about both the process of

making and the process of tooling,” says Eckart Maise of the Eames Office. “Understanding the complexity of the shape, and what the shape meant to the tooling and production, was a real technical challenge. It was fascinating to understand the nature of this sculpture, and how it is an artistic expression but also a technological experiment.”

The team was also surprised by how ahead of their time the Eameses were. “I’ve been making molds for twenty years, and this is the first mold I’ve made with this very special feature,” says Felix Buddenberg. “Because we have two overlapping areas, we had to construct the aluminum mold in a way that we can bring the pressure to both areas, and so we have a moveable part in the tool to realize this. It is amazing

that Charles and Ray did this already back in the 1940s.”

“We knew that bringing back this beautiful historical piece would teach us something about Charles and Ray’s process,” says Eames Demetrios, Director of the Eames Office. We now have a better understanding of the sculpture itself and a new appreciation for how far ahead of their time the Eameses were, and how the sculpture led to the design of the Eames LCW and so many other iconic pieces.”

Each of the limited edition Plywood Sculptures is an individual work of craftsmanship, made by carefully positioning layers of palisander veneer by hand, and then pressing those layers in a heated mold to achieve a sculpted plywood form with compound curves. While the 1943 sculpture had walnut veneers as the outer layer, the limited editions have been made with Santos Palisander because its wood grain has a similar energy to that of the walnut used in the Eameses’ era.

As Eckart Maise explains: “The limited edition is true to the historic sculptures in size and shape; each of them is numbered and labeled for authenticity. However, there are subtle inherent differences in each of

the twelve Plywood Sculptures. Each is unique because of the natural variation in the wood – both in the appearance of the wood grain as well as in how the individual wood veneers respond to the process of making. Each sculpture is finished by hand, and because of this human touch, there are slight differences in each of the twelve.”

While the sculpture is a piece to be coveted by collectors, it is the hope of the Eames Office that some, if not all, of the twelve limited edition Plywood Sculptures will end up in museum collections, thus giving as many people as possible the ability to experience the sculpture for themselves.

“In everything they did, Charles and Ray were designing for the future,” says Demetrios. “By sharing their ideas and the expression of those ideas, we hope their work can continue to inspire designers and craftspeople to push deeper into their challenges, address the many problems that need solving, and create what the world needs – even if it has never been done before.”

Plywood Sculpture

Design: Charles & Ray Eames, 1943

Limited Edition Palisander, 2021

Dimensions: 95.3 × 68.6 × 33.0 cm

Materials: Sapeli Plywood, Palisander Veneer